New Concept Technology has the innovative manufacturing solutions and experienced services your medical organization needs to turn your medical device product ideas into reality. We provide automated medical device manufacturing solutions, however complex. From rapid prototyping to custom overmold and injection molding solutions, our capabilities address your unique manufacturing requirements.

As designs and materials for medical devices have become more complex, we have searched for ways to cut down on material costs and speed up the manufacturing process for the benefit of our medical clients. Our team of product and automation engineers have proven experience in the medical industry and are here to partner with product designers to manufacture your complex medical device components.

We offer the rapid design and prototyping capabilities you need to develop, test and manufacture products for your most critical medical procedures. With our rapid medical prototyping services, your organization can:

New Concept Technology’s facilities are among the best in the world with a state of the art class 100K clean room, ISO 14644-1 Class 6 Certified, (Federal Standard 209E 100,000).

We excel in meeting all customer quality requirements from receipt of raw material through final inspection of finished product. Configured with flexibility in mind to support our wide range of medical manufacturing and assembly services, we’re ready to serve your needs.

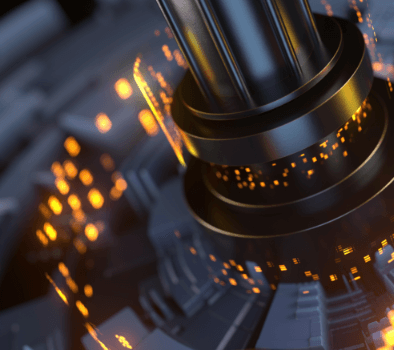

We use innovative molding equipment and extensive molding experience to assist with medical device molding needs. We offer both overmolding and injection molding services to meet your project’s unique requirements.

We specialize in custom overmold solutions for medical products. Our extensive experience enables us to offer high-value services in a rapid timeframe. Our expertise resides in:

We’re pioneers in advanced molding efficiency and manufacturing, driven by our customer-first philosophy and desire to satisfy your unique injection molding requirements. Our expert team offers rapid prototype medical device molds and mold tooling production for medical institutions and companies. With our injection molding capabilities, your organization can experience more project flexibility and extraordinary results.

We’re an established industry leader in fabrication and assembly concepts. We prioritize safety, quality and efficiency throughout all of our assembly processes to ensure you get the most value from your medical devices. With our assembly services, you can trust you will get your innovative product on time and with a competitive edge.

Each of our assembly options is customizable to meet your production needs. We follow efficient assembly processes to enhance your product’s quality while providing cost savings. From proof of concept to steady state production, our expert assembly services include:

New Concept Technology offers tailor-made solutions for your organization’s unique manufacturing needs. Our processes have been proven to enhance product quality while optimizing operational efficiency. With extensive design expertise, decades of experience and the industry’s best tools, we meet your quality requirements from the moment we receive your raw material to final inspections for your finished product.

We pride ourselves on having some of the best facilities in the world. We hold ISO 14644-1 Class 6 (Federal Standard 209E 100,000) and ISO 13485:2016 certifications to show our commitment to high clean room and quality management system standards. Configured to prioritize flexibility, our location is equipped with everything we need to offer a wide range of medical manufacturing and assembly services that address your needs.

At New Concept Technology, our primary goal is to provide medical manufacturing solutions that deliver quality products and ensure your success. We use innovative molding technology to bring your device ideas to life. Our superior customer service and exceptional engineering expertise set us apart in many markets, including the medical device market. Contact us online today to learn more about what makes us a great injection molding partner.