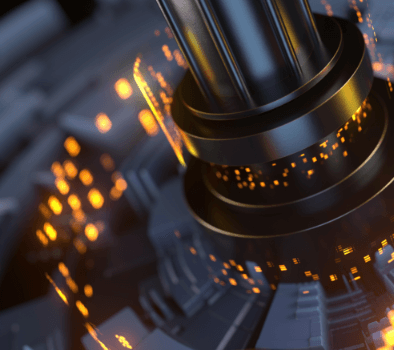

Tooling fabrication is a meticulous process that requires high-quality materials, specialized equipment and absolute attention to detail. At New Concept Technology, we curate superior quality through innovative expertise.

Our tool fabrication service is unlike any other. We design, assemble and implement custom tools for various applications. Whether your requirements involve plastic, metal, or composite materials, we can help deliver the customized tool solution you need to execute any job seamlessly.

Our injection and insert molding services allow you to explore numerous possibilities until you obtain your required tool shape. You can approach us with your concept or allow us to use an existing mold. Either way, you’ll be satisfied with the end product.

Beyond our proud heritage of in-house tool fabrication, we have proven that our self-sufficiency in tool design, fabrication and manufacturing execution provides our customers the ultimate quality and performance they need.

State-of-the-art tool-building equipment, toolmaker experience and our certified toolmaker apprenticeship program authenticate our commitment to stamping, molding and automation tool superiority. Working collaboratively with our customers, our design team and toolmakers run with an idea concept and apply various capabilities until the desired fabrication tooling outcome is achieved.

The process of designing, cutting and shaping materials into custom tools is an art in its own right. Tooling fabrication makes it possible to tailor custom cutting tool solutions to specific tasks or applications. With a custom shape, tools offer superior precision and accuracy in their function.

Custom tool fabrication can be applied in businesses across industries, including:

You’ll enjoy the following benefits regardless of your industry when choosing New Concept Technology for custom tooling and fabrication:

Our certified toolmakers can design, build, repair and maintain stamping dies, mold tools and assembly equipment. Our team is experienced in CNC Wire & Conventional EDM, Hole Pop, Grinding and embedded tool monitoring electronics. We’re ready to bring your ideas to life with manufacturing magnificence. Because we handle the entire tool fabrication process in-house, we can offer our customers fast turnaround times.

With immaculate operations, rapid prototyping, manufacturing test platforms and expert logistical support, New Concept Technology will rationalize the optimum time-to-run tooling for an on-budget, rapid time-to-market solution.

Because we run the tooling we’ve built under the same roof, we inspire an extraordinary level of accountability for performance, maintainability, quality, reliability and overall cost efficiency. Further augmented by our continuous improvement philosophy, we’ve raised the bar for operational standards.

We understand what it takes to maintain manufacturing excellence in an ever-changing market. Industry leaders look to New Concept Technology to solve their toughest challenges because we have the breadth of expertise and experience to fine-tune tooling for total process synergy.

Self-sufficiency in tool design, fabrication and manufacturing requires a steady flow of dedicated skilled professionals. We maintain that flow through our Apprenticeship Program. With this approach to talent acquisition, we seek only the best and most proficient in mathematics, communication skills, motivation and mechanical aptitude. Our apprentices undergo strenuous training and testing as part of the program, ensuring they can apply their skills in real-life tooling fabrication projects.

Part of this is the requirement for testing throughout the state-approved 5-year, 10,000-hour certification process. Every six months, apprentices are required to independently design, fabricate and validate their own tools for manufacturing. This challenge identifies the apprentices who rise to the occasion of design excellence and fabrication innovation. These star apprentices are then selected as cream of the crop upon certification.

Our commitment to appointing top recruits ensures our team can deliver quality manufacturing consistently. We achieve this by preparing them at the onset through the Apprenticeship Program. Our apprentices learn how everything is done in-house for optimal results and improved onshore efficiencies.

Partnering with New Concept Technology ensures you receive the best workmanship and toolmaking services available so you don’t have to look for innovative tool fabrication solutions elsewhere.

Are you interested in becoming a tool and die maker? Read more about our registered apprenticeship program.

Through our 5-year apprentice program, you can access a pathway to become an expert artisan. Gain nationwide accreditation and credits towards an Associate Degree to open a world of career opportunities. All training costs are covered, and you can earn an income while acquiring the Journeyperson credentials and skills that we value.

At New Concept Technology, our values focus on providing superior customer service. Our quality policy showcases our commitment to consistently delivering quality tool fabrication capabilities.

With cutting-edge automated 3D metrology systems and advanced data analysis tools, our skilled artisans can coordinate fabrication processes to provide high-performing results.

By investing in tool manufacturing services from New Concept Technology, you secure expert service with exceptional cost-efficiency and value propositions. We don’t compromise on quality, ensuring we deliver the best custom tools to suit your unique requirements.

Get a quote online for your tool fabrication projects or fill out our online contact form to learn more about our toolmaking services.