If you need a metal stamping company near you to create a new product, trust New Concept Technology to use the most versatile and efficient manufacturing process to get it done right. We are pioneers of industry-leading metal stamping solutions and have been entrusted by multinational Fortune 500 companies to perform high-quality work.

With our precision metal stampings and in-house premium tolerance tool fabrication, we can produce parts of material down as thin as .004 thickness. This ability allows us to deliver superior value solutions with competitive authority.

When our valued customer needed a structural part to brace a pull-to-release tab for a rapid disconnect system on a high speed data communications transceiver module, they naturally approached New Concept Technology for support.

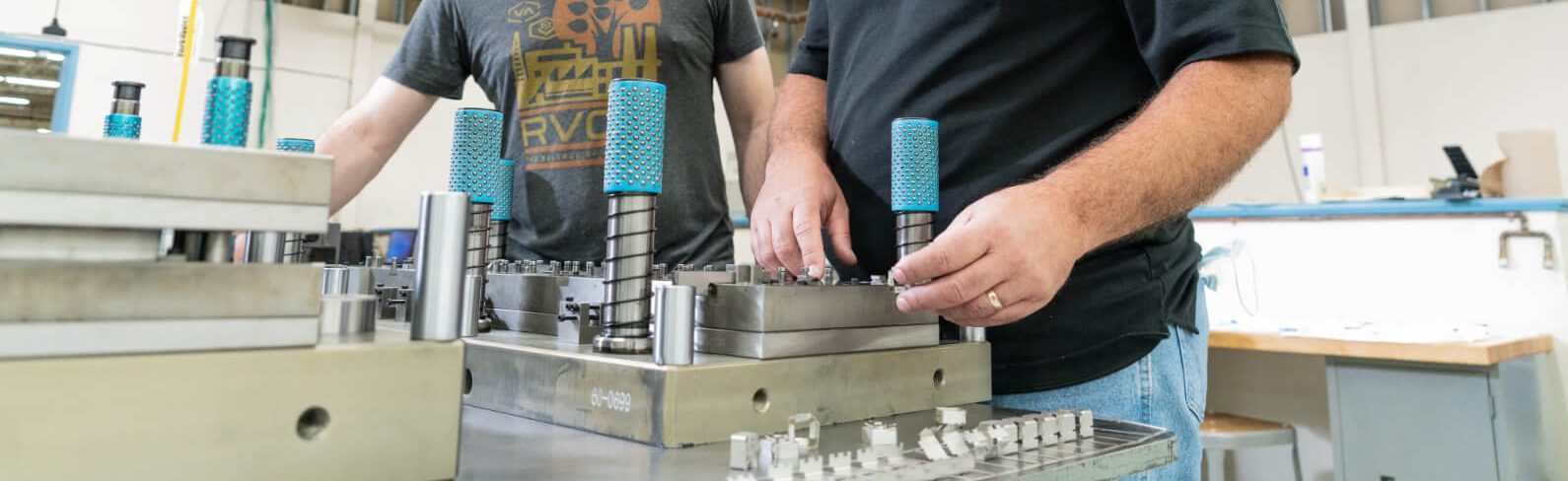

The solution needed to accommodate two “U-ups” ½” apart with holes to support a small diameter pin inserted through the captured pull-tab, a critical alignment specification challenge for the required 301 stainless steel, 1/4 hard, 0.508mm {0.020”} thick material.

With resolve and perseverance, New Concept Technology developed an innovative cost effective stamped & formed design solution that resolved the critical alignment challenges.

Running the in-house design/built stamping die tool with special lubricants to mitigate high wear issues common with heavy gauge stainless steel materials, we were able to seamlessly support varying demand from 1,000pcs to over 15,000pcs per month. Our progressive die stamping experience is what allows us to satisfy customer projects and bring their design to life.

Success with this somewhat atypical stamping application demonstrates our inherent agility and broad expertise in providing outstanding competitive solutions. Stamping processes require innovation to stay with the times and we’ve always aimed to provide the latest technology for our customers.

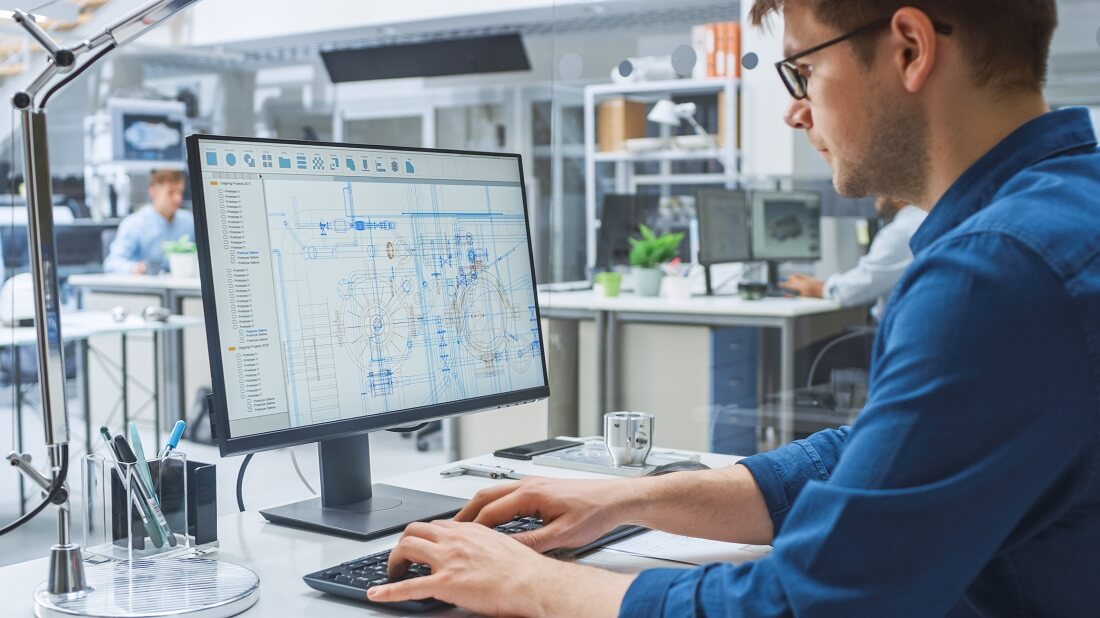

From our very inception, New Concept Technology has committed to in house design and fabrication of superior high speed stamping tools to complement our manufacturing operations. With 24/7 tool services, 45 certified toolmakers and our own accredited 10 strong Apprenticeship Program to support our business growth in manufacturing excellence, there’s no better choice for cost efficient rapid time to run high speed stamping solutions.

We have a team of expert designers in-house to collaborate with you to optimize a design for your next project. We can ensure your product meets required criteria for maximum profitability with metal stamped and formed components.

We understand the importance of cost solutions. Our team of experts will work with you to design & develop an innovative product that lasts.

The mechanical design of our manufacturing process is the foundation of cost-effective, high-quality manufacturing solutions. Our in-house fleet of Bruderer presses can perform metal stamping and forming through complex electrical and electronic contacts on an extensive size range. This process can be used for prototype and pre-production volumes, as well as full-scale high-volume production.

By converting bulk copper and ferrous alloys with inlaid materials when needed, our precision stamping capability allows us to produce high-quality products in rapid timeframes.

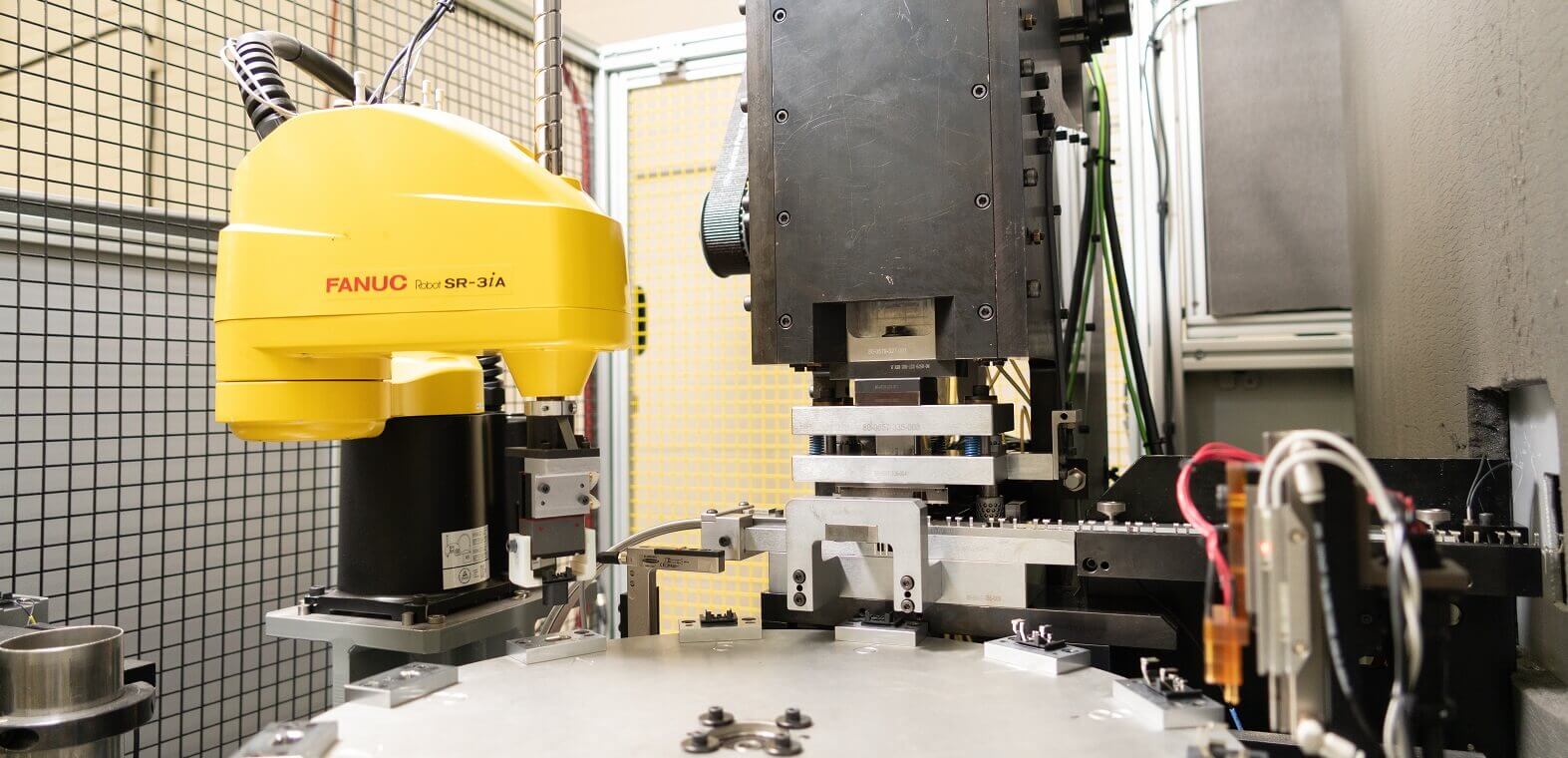

New Concept Technology is dedicated to driving innovation in process integration to boost the efficiency of our manufacturing operations while maintaining the integrity of our designs and finished products. We continue to pioneer reel to reel stamped and formed components with various molding technology and automatic assembly equipment to deliver premium value, high-quality United States-based manufacturing solutions for you.

Our precision metal stamping process lets us seamlessly integrate customized designs into your products for a branded, professional look.

At New Concept Technology, we are committed to providing first-rate service and quality custom manufacturing to meet your specific project needs. We can turn your dream into a reality by collaborating with you during the design process and fabricating your custom product with in-house resources and expert team members.

We have years of experience creating unique, innovative tools and products for a variety of industries. Our optimized, full-service manufacturing process ensures we can get the product into your hands as soon as possible.

Get in touch with one of our experts today by filling out our online form or calling 717-741-0840 to learn more about how we can help manufacture your product.