Do you have a project in mind that requires a customized touch? With insert molding, you can get the perfect component to suit your manufacturing needs. New Concept Technology offers custom insert molding to help you bring your final product to life. Our experts will work with you to deliver high-quality results in a short period.

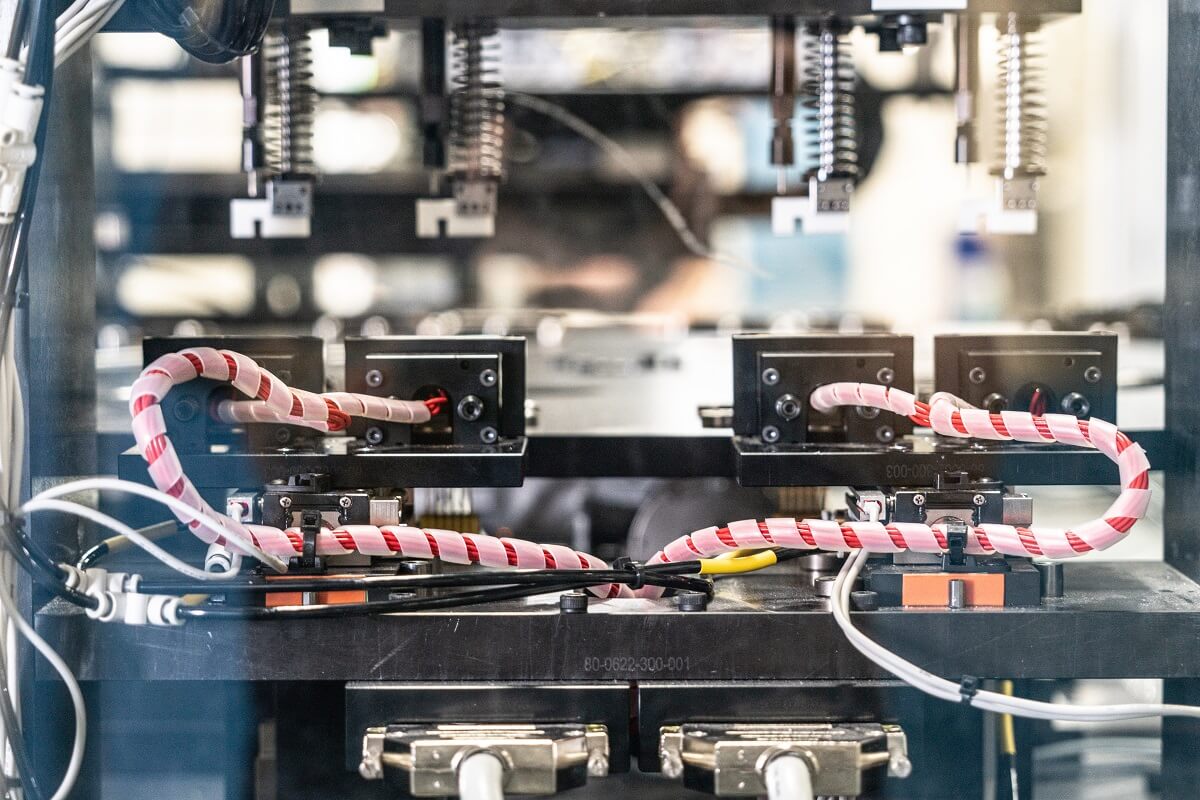

During the process, we will use a robotic arm to insert a metal component into a molding cavity to achieve a specific shape. We then allow the plastic to enter the mold, covering the metal component and forming the required shape.

The primary purpose of insert molding is to incorporate the desired properties of metal and plastic into one product. Popular applications for insert molding include wiring, insulated pipes and tools, such as screwdrivers. Manufacturers often use insert molding to protect metal components with a durable plastic layer.

New Concept Technology is an insert molding company that takes pride in crafting products that surpass your expectations. We use a six-axis robotic arm with laser displacement technology to ensure precision when placing the metal into the molding cavity. Once the metal emerges from the molding cavity, we use robotic soft sensing to follow the metal item as we transfer it to the next production stage.

New Concept Technology serves various Fortune 500 companies, assisting them with specialized insert molding services. We have a team of well-trained experts who will ensure excellent molding results. Our goal is to meet your unique needs and promote a smooth production process.

When you work with New Concept Technology for custom insert molding, you receive a range of benefits, including:

There are various types of molding, but insert molding offers manufacturers unique advantages, such as:

When you need top-notch insert molding, you know who to call. New Concept Technology will ensure your manufacturing process goes smoothly. Contact us to get a quote for custom insert molding.